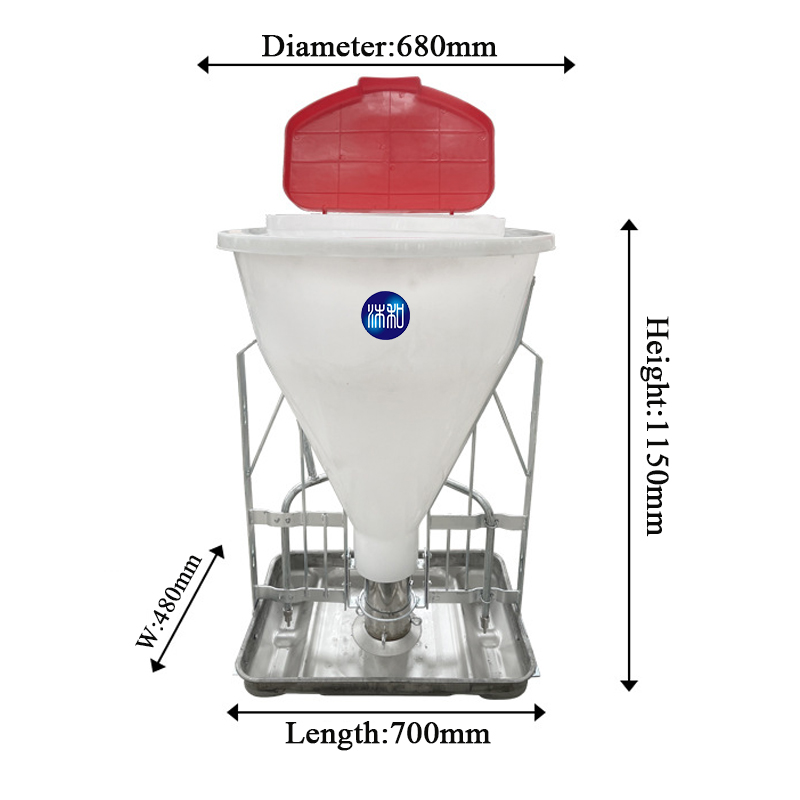

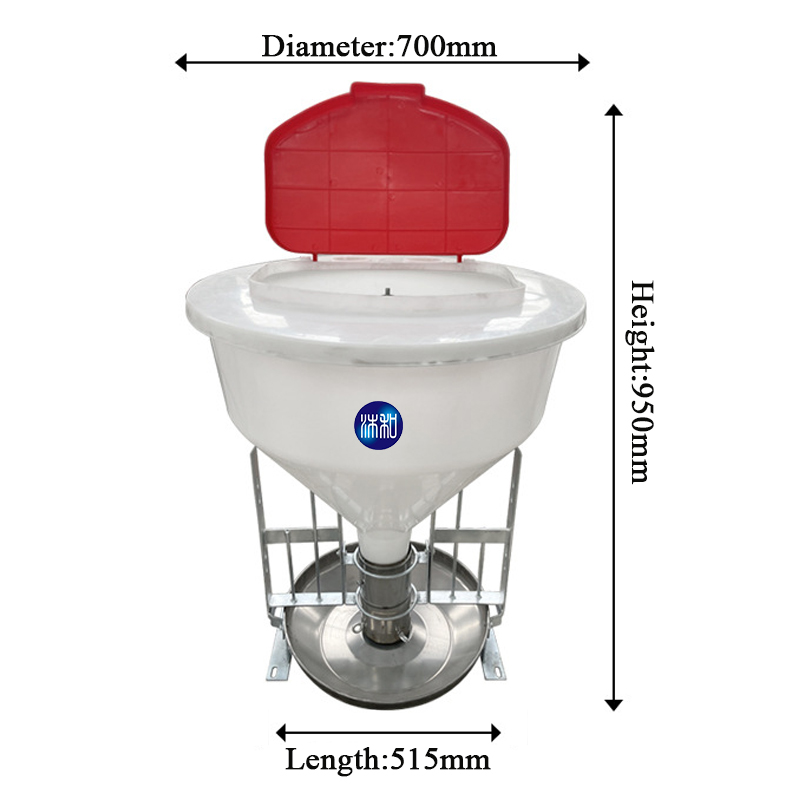

*Wet trough & wet and dry trough

*Capacity´╝Ü80kg/90kg/100kg/120kg

*Plastic barrels

*Stainless steel bracket and tray

Dry and wet feeders are composed of a material barrel, a material (water) trough, a material barrel material (water) trough bracket connection and fixing device, a feeding port, a collision type feeding device, a drinking water conveying pipeline, a feeding amount adjustment mechanism, etc.

It is mainly used for the breeding of nursery pigs and fattening pigs . The main material of the wet and dry feeder for pigs is plastic, which is one-time injection molded. It has good toughness and strong aging resistance. The fixed frame is made of hot-dip galvanized material, which has a long service life and is not easy to use deformation.

The wet and dry feeders produced by our company adopt multi-level adjustment, and the discharge can be controlled at will. The interior adopts a full-drive automatic feeder , which can discharge the material evenly, and the chassis is round and has no dead corners, so no material is hidden . The dry and wet feeder for pigs can save feed, reduce costs and reduce waste .

The wet and dry feeder has a special feeding mode, which can be used for both nursery pigs and fattening pigs, reducing feed waste. The effect is better when used in conjunction with the automatic feeding system. It greatly reduces the labor intensity of breeders, avoids waste, reduces costs, and increases benefits. The stainless steel bottom tank and dosing device are easy to clean and disassemble .

Wet and dry feeders are also called automatic wet and dry feeders, and wet and dry feed troughs. They are mostly used in the pig fattening stage of the pig farm production process. The wet and dry feeder is composed of a stainless steel chassis, a plastic barrel, a thickened galvanized plate bracket, a barrel cover, a galvanized U-shaped water pipe and other parts.

The barrel is also made of stainless steel. The wet and dry feeder has a hopper and a vertical feed tube. There is a plug at the bottom of the hopper, which is fixed on the central straight rod and passes through the vertical feed tube. There is a discharge stopper at the lower end. Feed is put into the hopper.

When the pigs are hungry, , raise the feeding stopper, lift up the feed stopper, put the feed into the trough, the pig eats, the feed rod returns, the feed plug closes, and the feeding stops temporarily. After eating the feed, the pig arches the rod again to release the feed until it eats.