Adjustable Pig Farrowing Crate

An increasing number of studies in recent years have demonstrated that restricting sow movement interferes with the expression of species-specific behaviors, such as nesting, orientation, exploration and communication with piglets, and leads to increased physiological stress. The stalls that can adjust the activity position of the sows came into being.

The entire pig farrowing crate is made of galvanized steel. The pig farrowing crate fence can be made of PVC or full steel. Galvanized aluminum is more durable than ordinary materials and has a long service life. Each stall of the pig farrowing crate is equipped with a food trough. It is convenient for sows to eat. The stall design of the farrowing crate ensures that the sows are not harmed when moving, and also ensures the survival rate of piglets in the sow's belly and prevents sows from miscarriage.

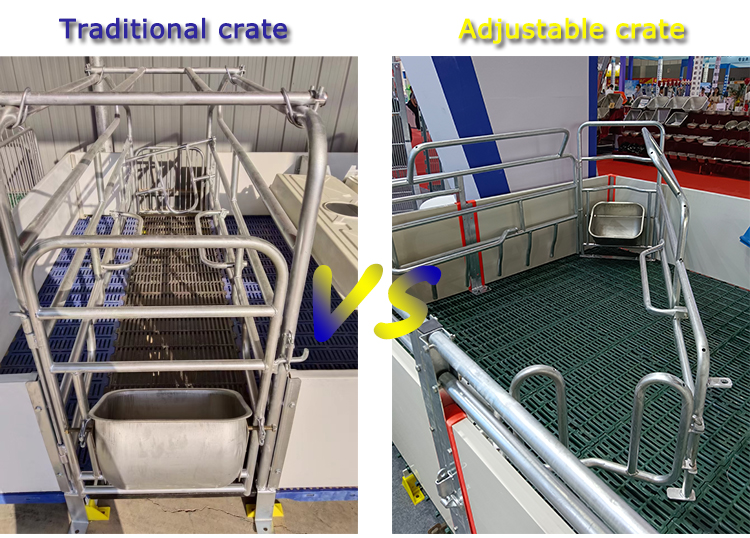

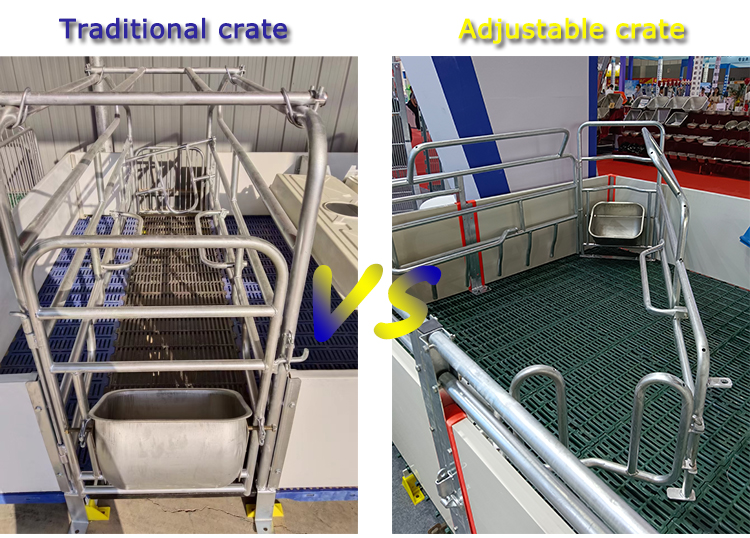

The width of the traditional farrowing pen is small and the sow cannot turn around. The anti-jumping crossbar above makes the space even tighter.

Different from common farrowing beds on the market, the adjustable farrowing bed gives sows more space to move, improving animal performance and welfare.

| Adjustable Farrowing stall |

| Specfication | 2400mm*2400mm*500mm |

|

| Material | Hot galvanizing steel pipe | Steel pipe+painting(optional) |

| Weight | 300kg |

|

| Sow stall | 1100mm in height |

|

| PVC fence | 500*30mm |

|

| The panel assembly | Stainless steel |

|

| Fixed base | FRP & Plastic |

|

| Floor system | 400*600mm | Sow weighted plastic plates |

| Heating equipment | Cover, lamp and lampshade |

|

| Sow trough | Stainless steel | Iron/steel(optional) |

1. Improve production efficiency: Sows can better demonstrate their growth and reproductive potential in an environment where they can move freely. Free movement helps to improve the fertility of sows and shorten the breeding cycle, thus improving overall production efficiency.

2. Reduce disease occurrence: Freely moving sows can maintain good physical condition, enhance resistance, and reduce the risk of disease occurrence. At the same time, free movement helps to detect and promptly deal with potential health problems and reduce losses during breeding.

3. Optimize meat quality and yield: In an environment where sows can move freely, their feed intake is more balanced, which is conducive to the digestion and absorption of nutrients. This helps to improve the quality of pork, optimize meat quality, increase lean meat rate and increase yield.

4. Reduce breeding costs: Free-moving sows can better adapt to the breeding environment, reduce stress reactions, and reduce mortality during breeding. In addition, free movement helps reduce feed waste and lower breeding costs.

5. Improve breeding efficiency: By improving sow production efficiency, reducing disease incidence and breeding costs, free-flow stalls can improve the economic benefits of breeding farms. At the same time, the market demand for high-quality pork is high, which will help further increase the profits of farms.

6. Comply with animal welfare requirements: Allowing sows to move freely is conducive to ensuring their basic animal welfare and reducing suffering during the breeding process. In our country, animal welfare issues are gradually receiving attention, and farms that meet animal welfare requirements will receive better policy support and market recognition.

1Q:Does this type of enclosure meet animal welfare requirements?

A:Allowing sows to move freely is conducive to ensuring their basic animal welfare.

2Q: May I change any part of the crate?

A: Of course you can, please check the technical data sheet and let me know what accessories you want to customize.

3Q: Can you OEM or ODM?

A: Sure, we certainly have solid creating group. The items can be created based on your demand.

4Q: What are your services?

A:We not only supply the equipment but also professionals to answer all questions, design exclusive pig farms for customers, install pig farrowing crate.

5Q: What is the average lead time?

A: The lead time is 15 days if the goods are in stock. For mass quantity order, the lead time is 20-30 days after receiving the deposit repayment.